Views: 23 Author: Julong Publish Time: 2022-12-14 Origin: aluminum panel systems manufacturer

The skin, the adhesive, the honeycomb core, the adhesive, and the skin are the typical layers of honeycomb panels. Aluminum, steel, and fiberglass are the best materials for skin because they have excellent tensile and compressive strength. Binders differ depending on their application: high strength, high temperature, low temperature, and so on. Depending on the design requirements, manufacturers can provide a range of honeycomb cores.

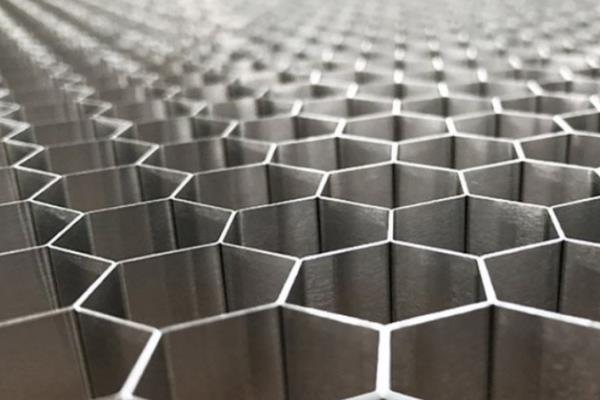

Cores of Honeycomb

Honeycomb cores range in strength and stiffness from paper and card for low-load applications such as interior doors for home usage to high strength and stiffness and very lightweight components for aviation structures. Honeycombs can be formed into flat and curved composite structures that adapt to composite curves without the use of excessive mechanical forces or heating.

Honeycomb material qualities are determined by the size (and thus frequency) of the honeycomb as well as the thickness and strength of the web material. Honeycomb cores can produce rigid and light laminates, however, due to their tiny bonding area, they are usually only utilized in high-performance resin systems, such as epoxy resins, to achieve the requisite adhesion to the laminate surface.

Honeycomb made of aluminum

The strength/weight ratio of aluminum honeycomb is one of the highest of any structural material. Aluminum foil comes in a range of bonding configurations and can be shaped into a variety of geometries (usually hexagonal). Variable foil thickness and cell size can also be used to control properties. Honeycomb is normally delivered in the form of an unexpanded block that is stretched into sheets in the field.

Aluminum honeycomb, despite its outstanding mechanical qualities and low cost, should be utilized with caution in some applications (e.g., huge marine constructions) due to potential corrosion difficulties in saltwater conditions. In such instances, care must also be made to avoid direct contact between the honeycomb and the carbon skin, as electrical conductivity might accelerate galvanic corrosion. Aluminum honeycomb is also free of "mechanical memory." When struck with a cored laminate, the honeycomb deforms permanently and the robust FRP skin returns to its original place. This can significantly reduce the mechanical characteristics of the area with unbonded skin.

Applications

1. Construction Products

Julong honeycomb panels offer a flat, strong, and stable framework that may be used as a backing material for metal, glass, stone, and other aesthetic surfaces in buildings. Wall cladding, ceilings, canopies, and elevator interiors are all examples of applications.

2. Commercial

Julong honeycomb panels have improved mechanical qualities, as well as resistance to moisture, chemicals, and impact, as well as vibration dampening. As a result, doors, decks, fixtures, custom furnishings, and other items perform better.

3. Ground Transportation

Aluminum Honeycomb Panel offers lightweight solutions for railroads, automobiles, trucks, trailers, leisure vehicles, race cars, military and specialized vehicles, and so on. Walls, doors, floors, ramps, ceilings, bulkheads, chairs, and storage are all examples of applications.

4. Marine and Recreation

Aluminum Honeycomb Panel has a high strength-to-weight ratio, making it suitable for a wide range of applications. A few examples include sporting goods, boat decks, bulkheads, hatches, and doors.

Our honeycomb panels, which are available in a variety of panel sizes and finishes, are intended for use in a wide range of typical applications and processes. They can be constructed to satisfy specific strength and stiffness requirements. Aluminum Honeycomb Panel is used in a variety of applications that demand better core shear, compression, and bonding qualities. To purchase, please contact us.